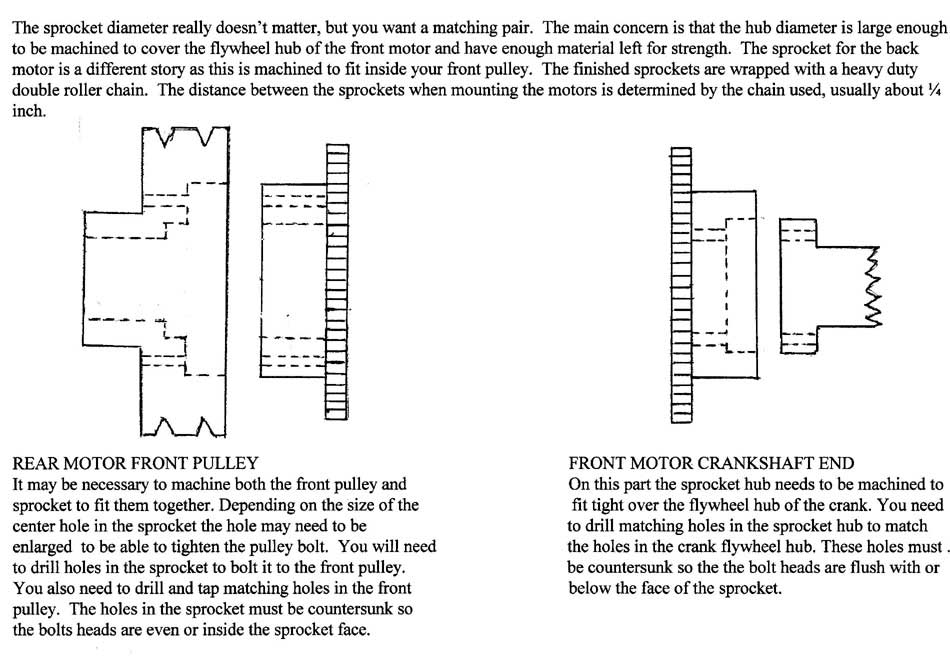

| ||||

How To: In-Line Engine Coupler

Norb Locke

Norb Locke

Norb Locke

Illustration

=

=

=

=

=

=

Norb has been our "Tech" advisor for several years. The question as how to couple two engines together comes up quite often. He put this illustration together so the info would be here for people to see.

Chain .... No 60 Heavy Duty Roller Chain Sprockets .... Depends on the size of the hub needed Phasing .... We put the chain on every way possible as far as timing the motors and never found a difference in time or speed.

Blue Angels Second Twin

How To: Side by Side

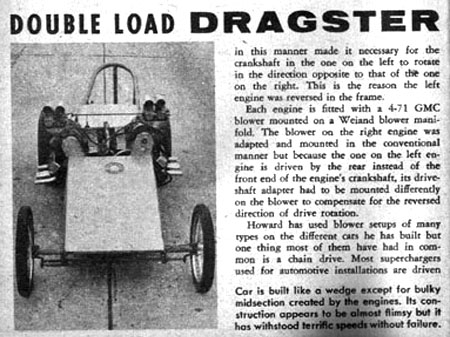

Doing It The Hard Way

Doing It The Hard Way

Doing It The Hard Way

We have found six different methods that were used in building a Side by Side Twin Engine drag or street car. They were:

Jazzy Nelson was the first - a special rear end with two center sections that let him have both engines rotating the same way. Also used by Eddie Hill and possibly

Jack Moss - don't have any pictures to confirm.

The Howard Cams Twin Bear - mounted one of the engines backwards, this allowed the engines also to rotate the same way to a single center section rearend. Also used by

Dye and Hampton, Knapp and Westerdale, and Ken Scott.

Tommy Ivo found a different and very successful way - both engines facing forward, one center section - but - one engine rotating in the opposite direction. All you needed was a camshaft that was ground to go the opposite way and a matching distributor gear. Also used by the Drag Master TWO THING.

Don Maynard had his own ideas when he built the Chris Karamesines Twin - which is also being recreated using Don's original drive gear - two engines facing forward, both rotating the same way, to one center section. Wish we had a picture of what was inside. Also the way Gordon Tronson built his Twin For The Street.

Mickey Thompson also had a Side by Side Twin - maybe the basis for a Salt Flat project but it spent some time on the drag strip - two engines via four wheel drive - one engine fed power to the front while the other fed power to the rear.

Last but not least Chet Herbert, maybe the only man who kept up with Mickey Thompson in the "Tried It All Department"- two engines side by side rotating the same way to two rear ends. Might have been short lived like his THREE engined dragster, but it happened.

Eddie Hill

Dragmaster TWO THING

Twin For The Street

Dye and Hampton

The Chuck Sarno - Jazzy Nelson Twin

Howard Cams Twin Bear

TV Tommy Ivo

Have to include a picture of the ultimate Side by Side along with the ultimate showman - TV Tommy Ivo and the Showboat.

Don Maynards solution which is about to be put back in service after 50yrs.

Mickey Thompson Chet Herbert

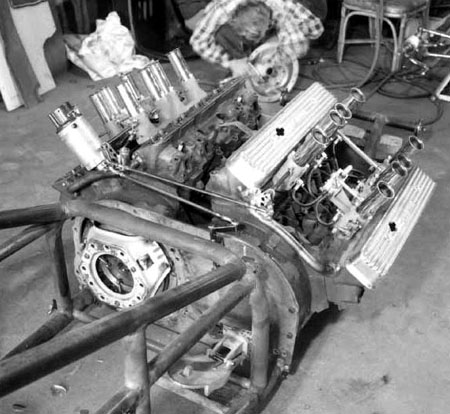

Nostalgia Twin Text provided by Rocky

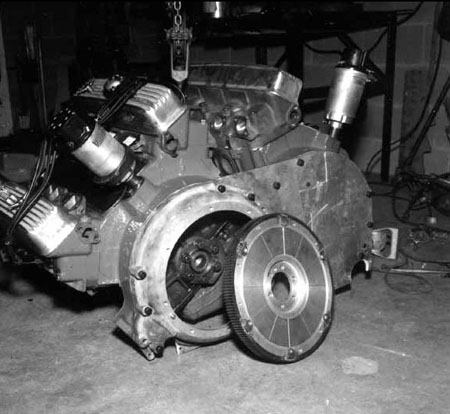

After making a pattern with the engines flywheels set at "0" clearance I drilled the engine

plate ( mounting holes only ) off the patern with near perfect results. I drilled out the holes to 7/16 and set the flywheels clearance with a .020 shim stock between the gears and clamped tight with a furniture clamp. With this all in place I then marked, drilled, and reamed the mounting dowel ( oversize ) holes to keep everything in place.

What I found is that all Ring Gears are not alike and purchasing all the gears at the same time from the same manufacture is a GREAT idea. My Ring Gears ( 2 on each flywheel ) are

spot welded to Billet Steel flywheels that I had the shoulder machined and careful attention was paid to aligning the teeth, being careful not overheat the Rings and upset the tooth spacing.

I have run my car some and there are no signs of ware on the teeth, and I don't believe there is as much stress on the teeth as one would think .... unless things went wrong.

I was fortunate to find an original Chris Craft / GM Marine REV engine rotation Cam and Gear Drive. GM used a Gear to Gear design that keeps the cam rotating normal rotation while the engine runs backwards. The beauty in this is there is no need for a special Distributor gear or Oil Pump mods, it is all stock pieces. I sent the cam to Clay Smith and he reground the cam as big as he could on a stock core, 280 DUR @ .050 and .480 Lift, anything bigger will require a Roller Cam I guess.

Norb's Flathead Twin